↓ Please scroll to the side to see.

| Product name | Non-volatile (%) |

Viscosity (mPa・s) |

pH | Mean particle size (nm) |

Acid value (theoretical value) |

Tg (℃) (theoretical value) |

MFT※ (℃) |

Characteristics |

|---|---|---|---|---|---|---|---|---|

| XP8812 | 41.0 | 500 | 9.0 | 50 | 61 | -9 | <5 | Moisture-proofness, Water resistance |

| XP8829 | 48.0 | 600 | 8.5 | 100 | 57 | -8 | <5 | Moisture-proofness, Water resistance, Application limited 176.170 Confirm, 176.180 Confirm. |

(*) minimum film forming temperature

↓ Please scroll to the side to see.

| Product name | Non-volatile (%) |

Viscosity (mPa・s) |

pH | Mean particle size (nm) |

Acid value (theoretical value) |

Tg (℃) (theoretical value) |

MFT※ (℃) |

Characteristics |

|---|---|---|---|---|---|---|---|---|

| NE-2260 | 49.0 | 600 | 8.0 | 90 | 53 | -10 | <5 | Application limited 176.180 Confirm, 176.170 Confirm |

| PE-2273 | 40.0 | 800 | 8.0 | 100 | 38 | -11 | <5 | FDA176.170, 176.180 Confirm, Heat-sealing |

(*) minimum film forming temperature

↓ Please scroll to the side to see.

| Product name | Non-volatile (%) |

Viscosity (mPa・s) |

pH | Mean particle size (nm) |

Acid value (theoretical value) |

Tg (℃) (theoretical value) |

MFT※ (℃) |

Characteristics | Remarks PVC content |

|---|---|---|---|---|---|---|---|---|---|

| BE-7500 | 30.0 | 400 | 8.0 | 65 | 45 | 38 | <5 | Pigment dispersion, Rub resistance | 50% |

| BE-7650 | 30.0 | 150 | 8.0 | 30 | 31 | 53 | <5 | Rub resistance | 65% |

| BE-7502 | 30.0 | 200 | 8.0 | 80 | 45 | 15 | <5 | Adhesion to substrates | 40% |

| BE-7503 | 30.0 | 50以下 | 8.0 | 50 | 50 | 56 | <5 | Alcohol resistance | 50% |

(*) minimum film forming temperature

↓ Please scroll to the side to see.

| Product name | Non-volatile (%) |

Viscosity (mPa・s) |

pH | Mean particle size (nm) |

Acid value (theoretical value) |

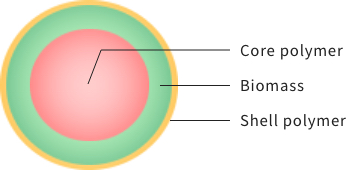

Biomass | MFT※ (℃) |

Characteristics | Biomass content |

|---|---|---|---|---|---|---|---|---|---|

| PE-2027 | 45.0 | 960 | 8.2 | 200 | 5 | Starch | <5 | Solvent resistance | 50% |

| PE-2189 | 45.0 | 600 | 8.3 | 100 | 155 | Rosin | <5 | Wet rub resistance, High gloss | 50% |

| NE-2309 | 40.0 | 800 | 8.5 | 60 | 51 | Fatty acid | <5 | Adhesive PET/PP/PS film | 20% |

(*) minimum film forming temperature